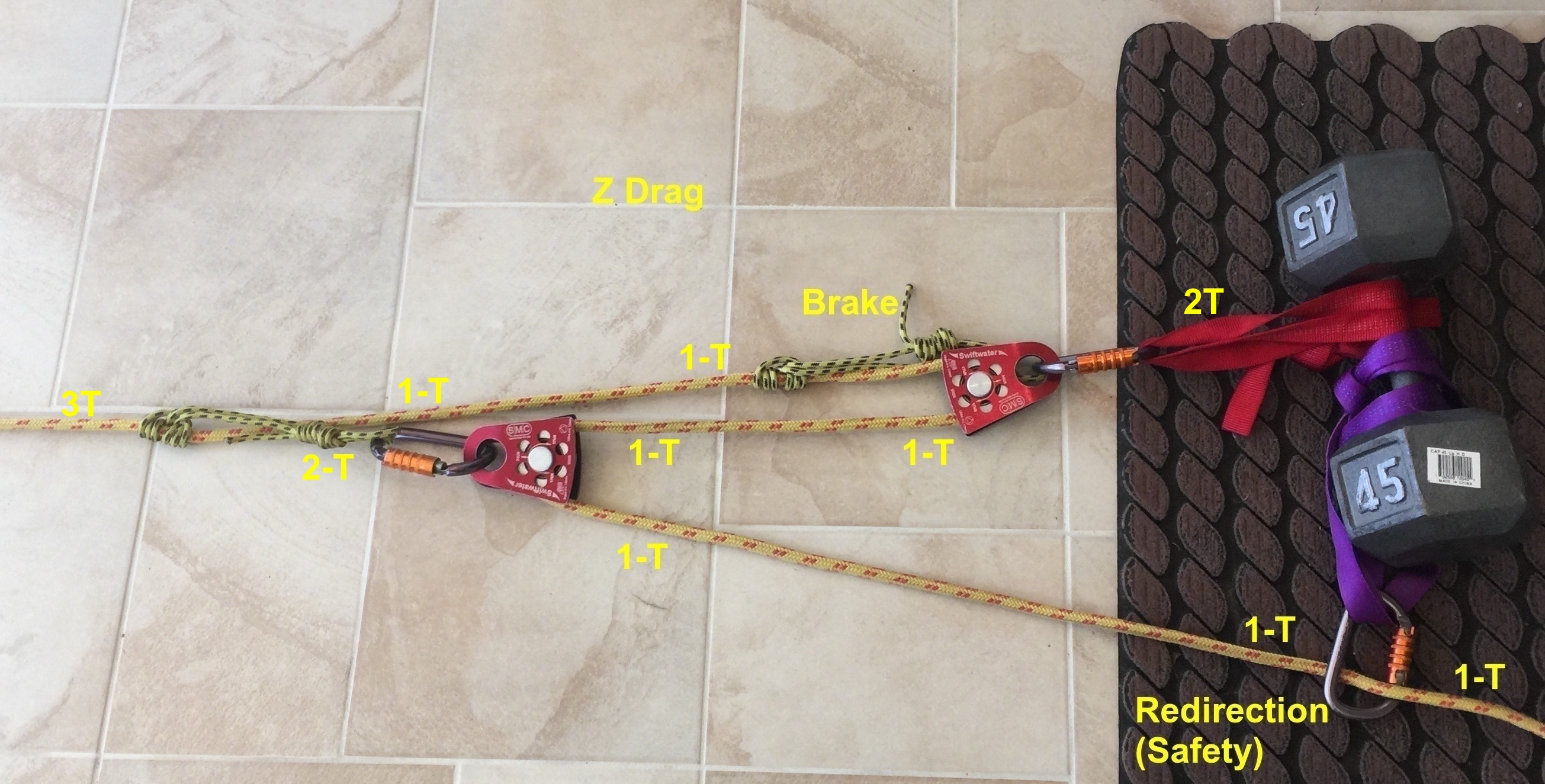

Most SWR classes teach the Z-Drag mechanical advantage system. The Z-Drag is confusing to many but many of us use this system every time we tie our boats to our cars with a Truckers Hitch or cinch down on a cam strap. The hitch or cam becomes our traveling pulley. Friction greatly reduces the effectiveness of this rigging - count on only a 2:1 advantage when using a carabineer as your traveling pulley. When purchasing a pulley, you need at least a 4:1 ratio between the rope diameter and the bend caused by the pulley to maintain rope strength. For our purposes, a 2" pulley is just about the right size. For prussic line diameter, 5 mm - 7 mm works well with 3/8" line - 7 mm is best. The following paper does a great job at explaining the various mechanical advantage systems: Understanding Mechanical Advantage Systems. If you want to see a simple Z Drag in action, check out the following video: Z-Drag in Action.

Most SWR classes teach the Z-Drag mechanical advantage system. The Z-Drag is confusing to many but many of us use this system every time we tie our boats to our cars with a Truckers Hitch or cinch down on a cam strap. The hitch or cam becomes our traveling pulley. Friction greatly reduces the effectiveness of this rigging - count on only a 2:1 advantage when using a carabineer as your traveling pulley. When purchasing a pulley, you need at least a 4:1 ratio between the rope diameter and the bend caused by the pulley to maintain rope strength. For our purposes, a 2" pulley is just about the right size. For prussic line diameter, 5 mm - 7 mm works well with 3/8" line - 7 mm is best. The following paper does a great job at explaining the various mechanical advantage systems: Understanding Mechanical Advantage Systems. If you want to see a simple Z Drag in action, check out the following video: Z-Drag in Action.

Take a closer look at the picture above. You will notice an extra Prusik on the load bearing rope back to the tree. This is a brake and enables you to ease off the pull line and still hold the load for awhile. You will probably need to advance the prusik knot as more rope is pulled else it will get caught in the pulley.

Another safety device is dampers. The following video uses a dynamometer to calculate the force on the load bearing end of a mechanical advantage system. This video also demonstrates the use of dampers to prevent the system from hurling rope and gear under force. The blanket adds some weight and quickly arrests the loosened gear: Mech Advantage with safety dampers

Another safety device is dampers. The following video uses a dynamometer to calculate the force on the load bearing end of a mechanical advantage system. This video also demonstrates the use of dampers to prevent the system from hurling rope and gear under force. The blanket adds some weight and quickly arrests the loosened gear: Mech Advantage with safety dampers

In this next video, we intentionally pulled a Z Drag to failure to demonstrate what happens. This is also a great example of the use of a directional change to keep us out of the line of fire: Z Drag with Directional Change.